Welding production line for aluminum alloy fluid container

Classification:

Key words:

Arc Welding Technology | Robotic System Integration | Automation and Intelligent Manufacturing

Detailed description

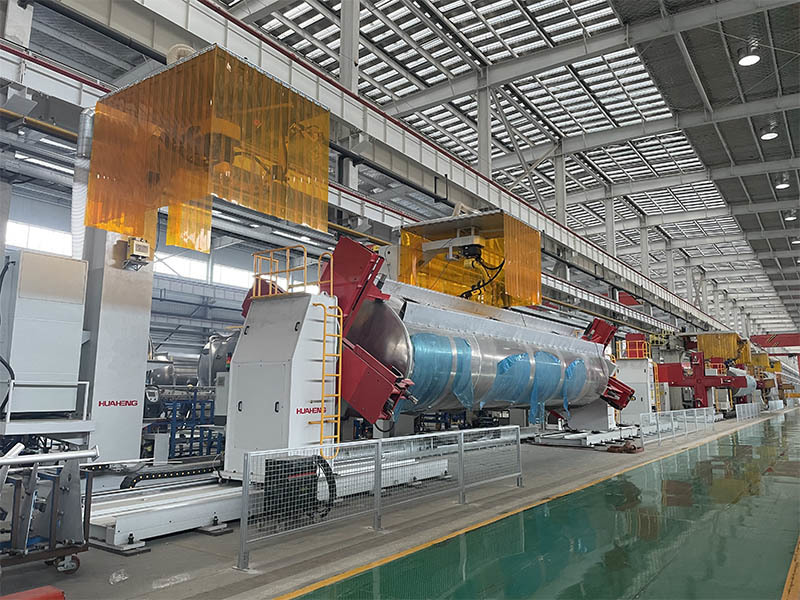

The aluminum alloy liquid tanker digital production line project is an in-depth exploration of aluminum alloy liquid tanker multi-species small batch production mode, the main technical highlights are as follows:

(1) Realization of efficient and flexible mixed-line production.

The production line is compatible with the mixed-line production of all domestic and foreign aluminum alloy liquid tank trucks, and realizes flexible production through working island and flexible tooling. At the same time, the mass application of welding robots, grouping tooling, AGV trolleys and omni-directional trolleys improves the passing rate of the products, reduces the labor intensity of the workers and improves the production efficiency.

2)、Efficient logistics methods are adopted.

Realized the first application of mobile carts within the module area and cross-area heavy-duty omni-directional carts in the automated production logistics of aluminum alloy liquid tank truck industry.

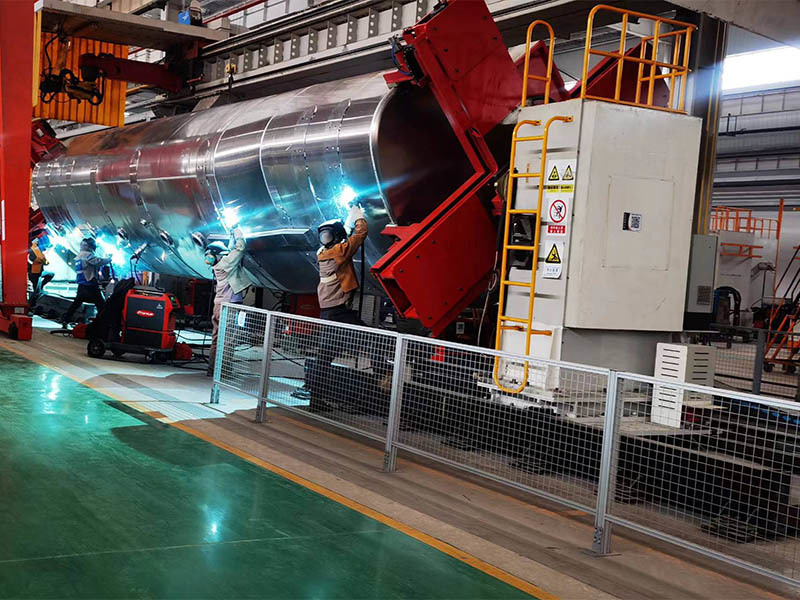

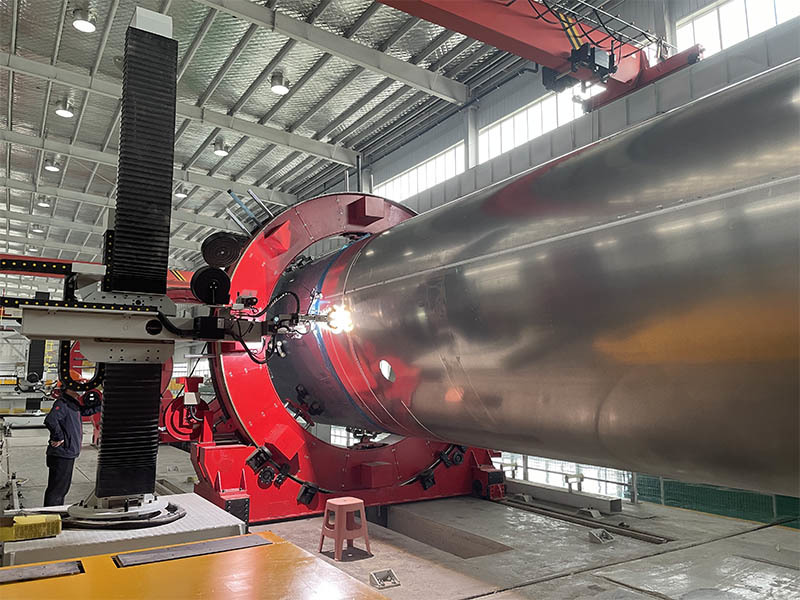

(3), robot vision, welding robot, parametric programming, offline programming and other advanced manufacturing technology exploration and application.

4), the application of a large number of interconnected and intelligent networking hardware equipment, realizing the docking with the MES system and improving the intelligent level of production and data collection.

The production line is planned to meet the boundary conditions stipulated in the technical agreement of all domestic and foreign aluminum alloy liquid tanker mixed line production, the cylinder splicing plate adopts automatic splicing method, manually assisted coiling and closed welding, the cylinder grouping adopts special machine-assisted grouping tooling equipment, brackets, payoff beams and other accessories using flexible grouping tooling, robot automatic welding, manual inspection and repair of the welding combination of production modes, through the automatic, semiautomatic and other means of logistics to improve the existing production mode. A variety of logistics means to improve the existing production model, improve production efficiency, reduce the operator's labor intensity, improve product quality, product qualification rate off the line to reach 96% or more. In addition to the appeal requirements, the site and related requirements required for the second phase of upgrading, such as three-dimensional warehouse, laser automatic discharging, automatic grinding, scribing, mechanically-assisted installation of anti-wave boards, automatic burnishing and priming of ring seams, automatic grouping of heads, truss manipulator transfer, AGV transfer, etc., are retained.

Inquiry

Xuzhou Huaheng Robotics Co., Ltd.

Phone: 0086-516-66882288

Kunshan Huaheng Robotics Co., Ltd.

Phone: 0086-512-87880678

Focus on Robot Division

Huaheng mobile phone terminal

Huaheng Company Public Number

Copyright © 2024 Xuzhou Huaheng Robotics Co., Ltd. All Rights Reserved