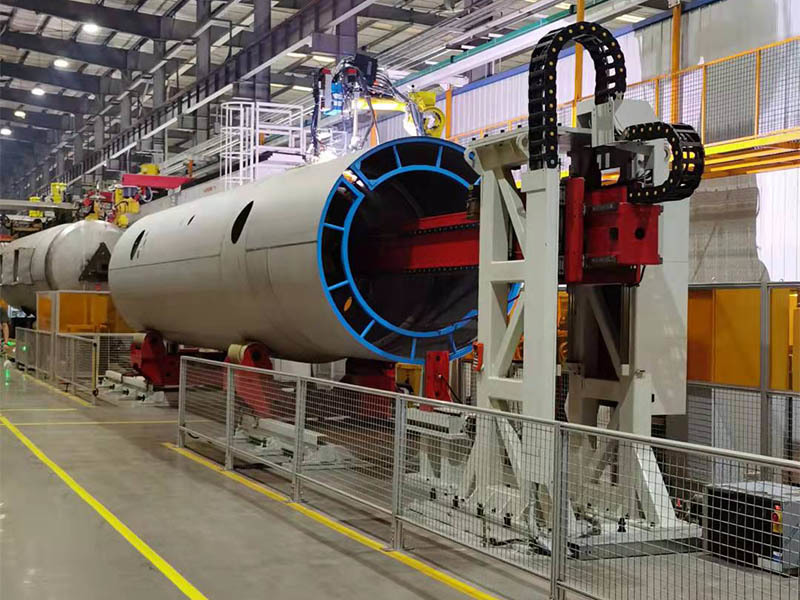

Welding production line for stainless steel liquid tanks

Classification:

Key words:

Arc Welding Technology | Robotic System Integration | Automation and Intelligent Manufacturing

Detailed description

This stainless steel liquid tank welding production line project aims at intelligence, flexibility and labor-saving, and adopts intelligent heavy-duty AGV trolley to realize the function of transferring materials between production stations. According to the capacity planning of 60min/trolley, it involves the cylinder body assembly station, anti-wave plate installation station, cylinder body ring seam welding station, heating tube assembly station, anti-wave plate welding station, anti-wave plate filler weld station, cylinder body accessories and Waveguard plate attachment installation station, gas test station, head assembly station, head correction station, head welding station, heating pipe welding station, heating pipe welding station, heating pipe welding station, heating pipe gas test station, cylinder attachment welding station, omega assembly station, omega welding station, bracket assembly station, bracket welding station, and all other welding processes, which can be realized by on-line flaw detection. Most of the equipment in this project belongs to the first set in the industry, and a large number of new processes and technologies are applied in this production line, which mainly contains:

1.P+T process robot ring seam welding (first set)

2. Wave plate station 4 robot intelligent welding (the first set)

3. Heating pipe automatic grouping point solidification (the first set)

4. Double-robot intelligent welding of heating pipe (the first set)

5. Double-robot intelligent welding of cylinder attachment (first set)

6. Intelligent grouping of omega bracket (first set)

7. Intelligent dual-robot welding of OMEGA bracket (first set)

8.Non-demonstration application - parameterized programming application (first of its kind)

9.Whole line data collection docking MES system

10.Stainless steel thin plate parts welding

Batch application of laser real-time tracking technology on stainless steel tank project

Inquiry

Xuzhou Huaheng Robotics Co., Ltd.

Phone: 0086-516-66882288

Kunshan Huaheng Robotics Co., Ltd.

Phone: 0086-512-87880678

Focus on Robot Division

Huaheng mobile phone terminal

Huaheng Company Public Number

Copyright © 2024 Xuzhou Huaheng Robotics Co., Ltd. All Rights Reserved